Excellent resistance to wear and virtually no maintenance….

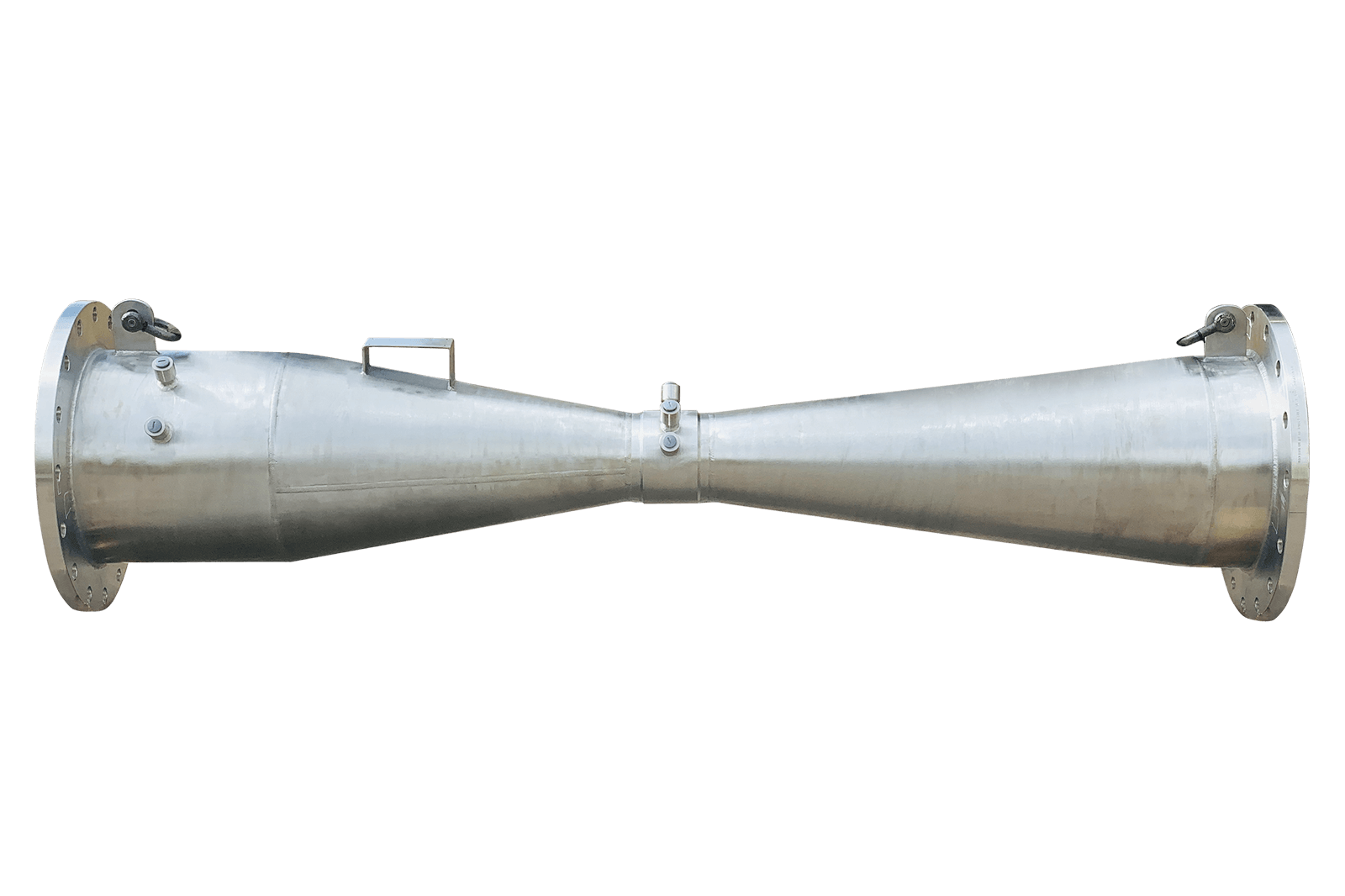

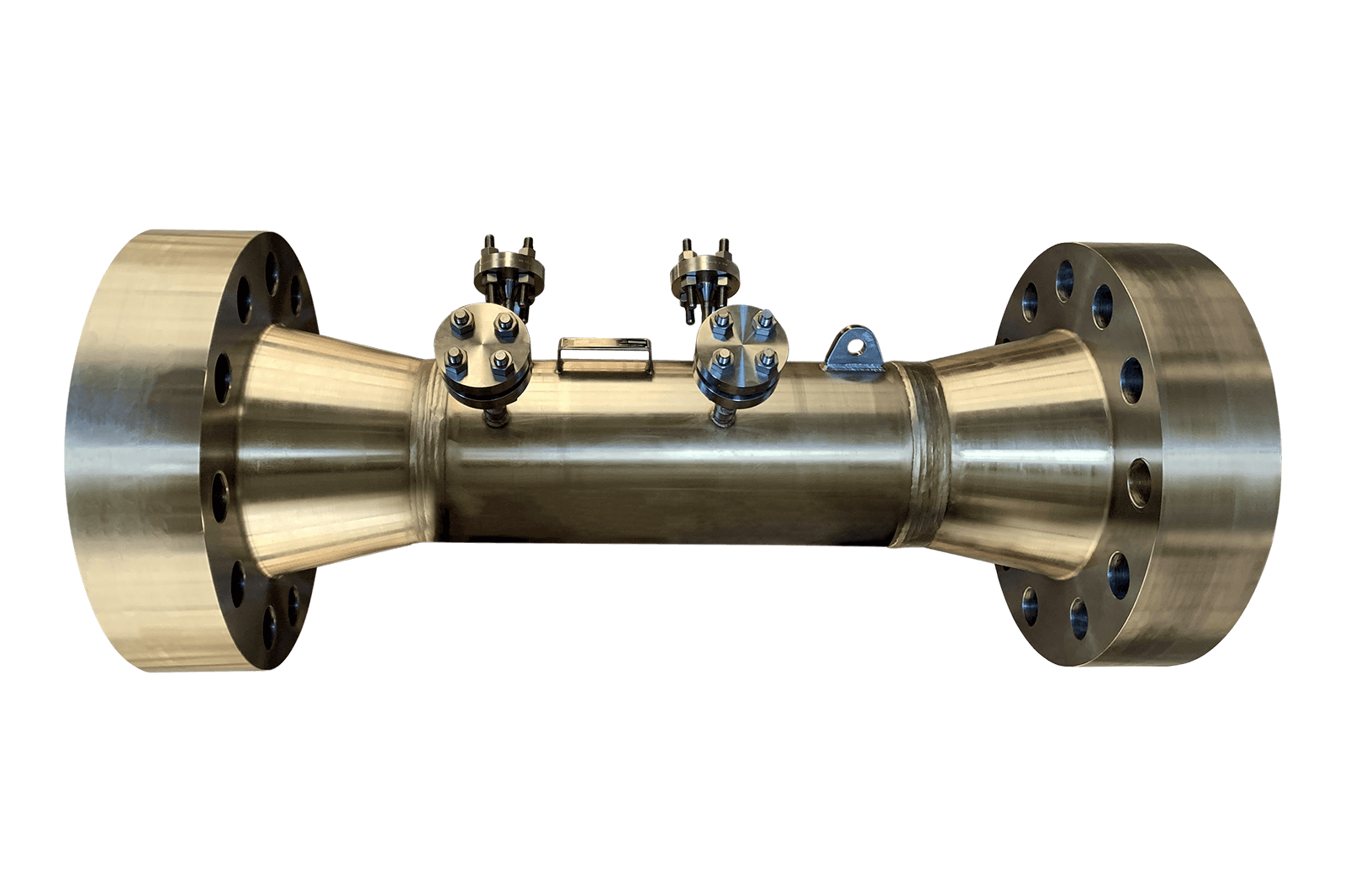

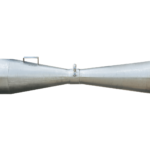

Venturi tubes offer excellent resistance to wear and consequently require virtually no maintenance. They have a very long service life which is typically the whole life of the plant on which they are installed.

They produce a low net pressure loss and therefore reduce energy costs by typically 20 to 25%, with a consequent reduction in greenhouse gas emissions.

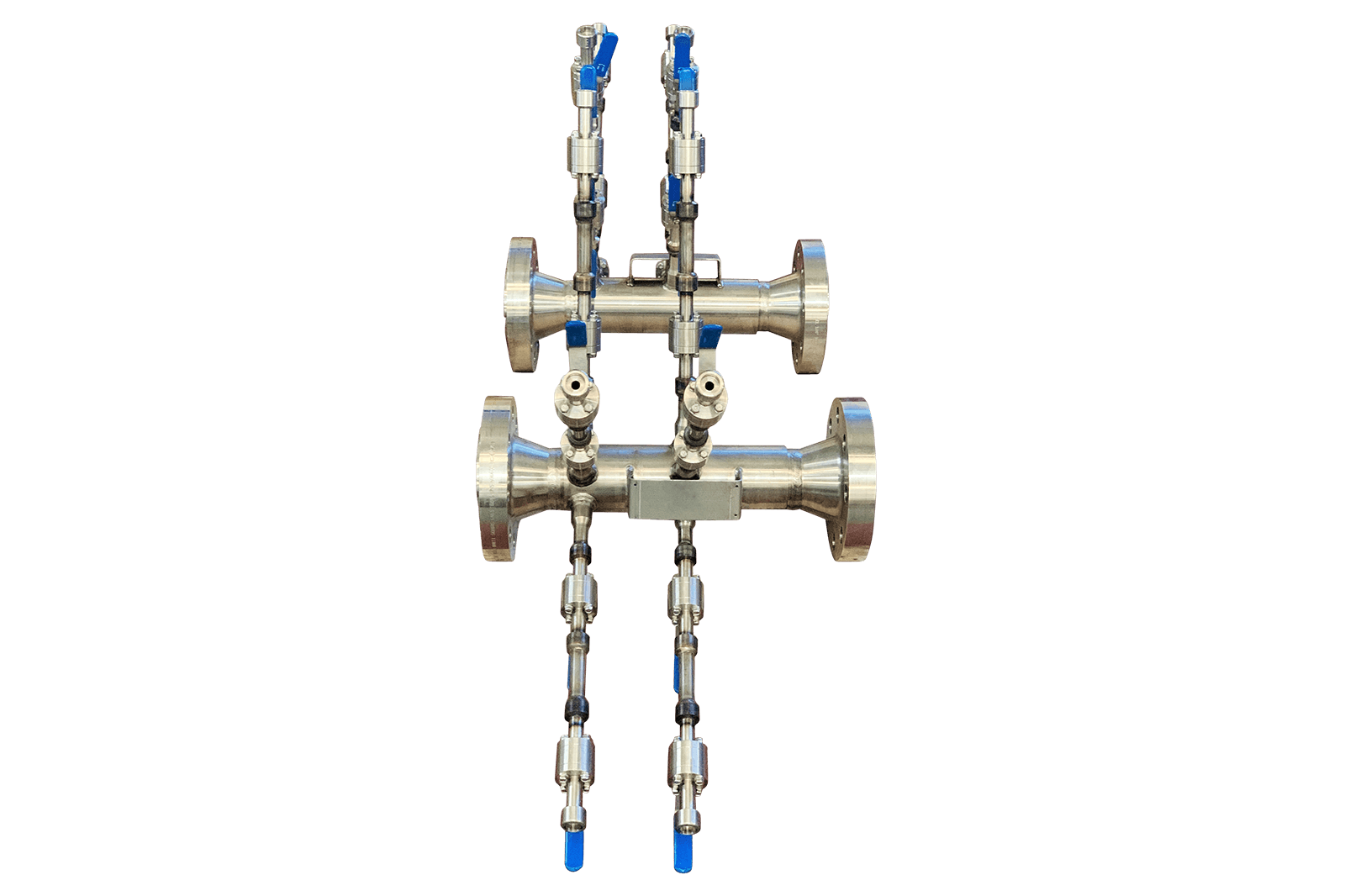

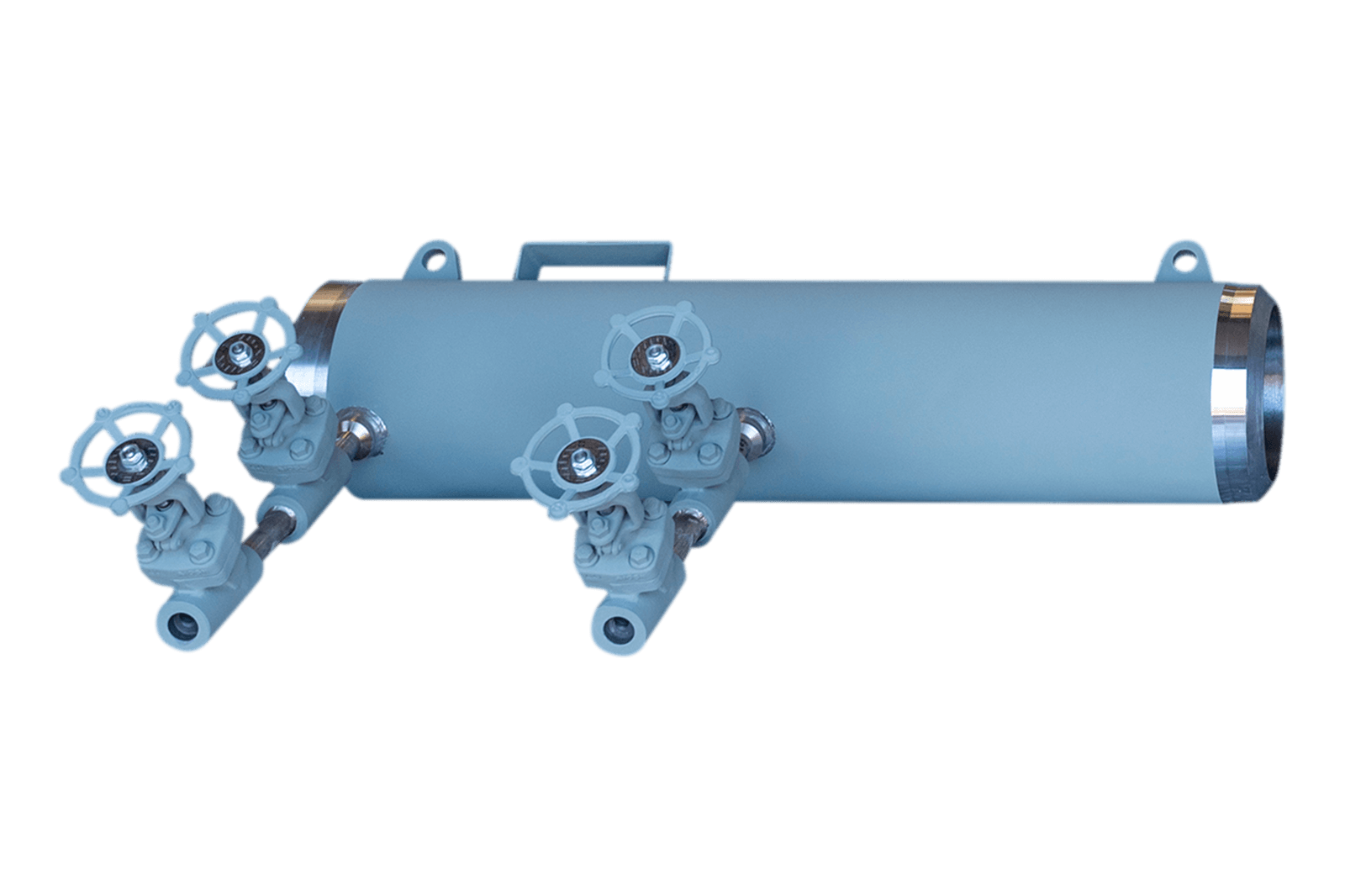

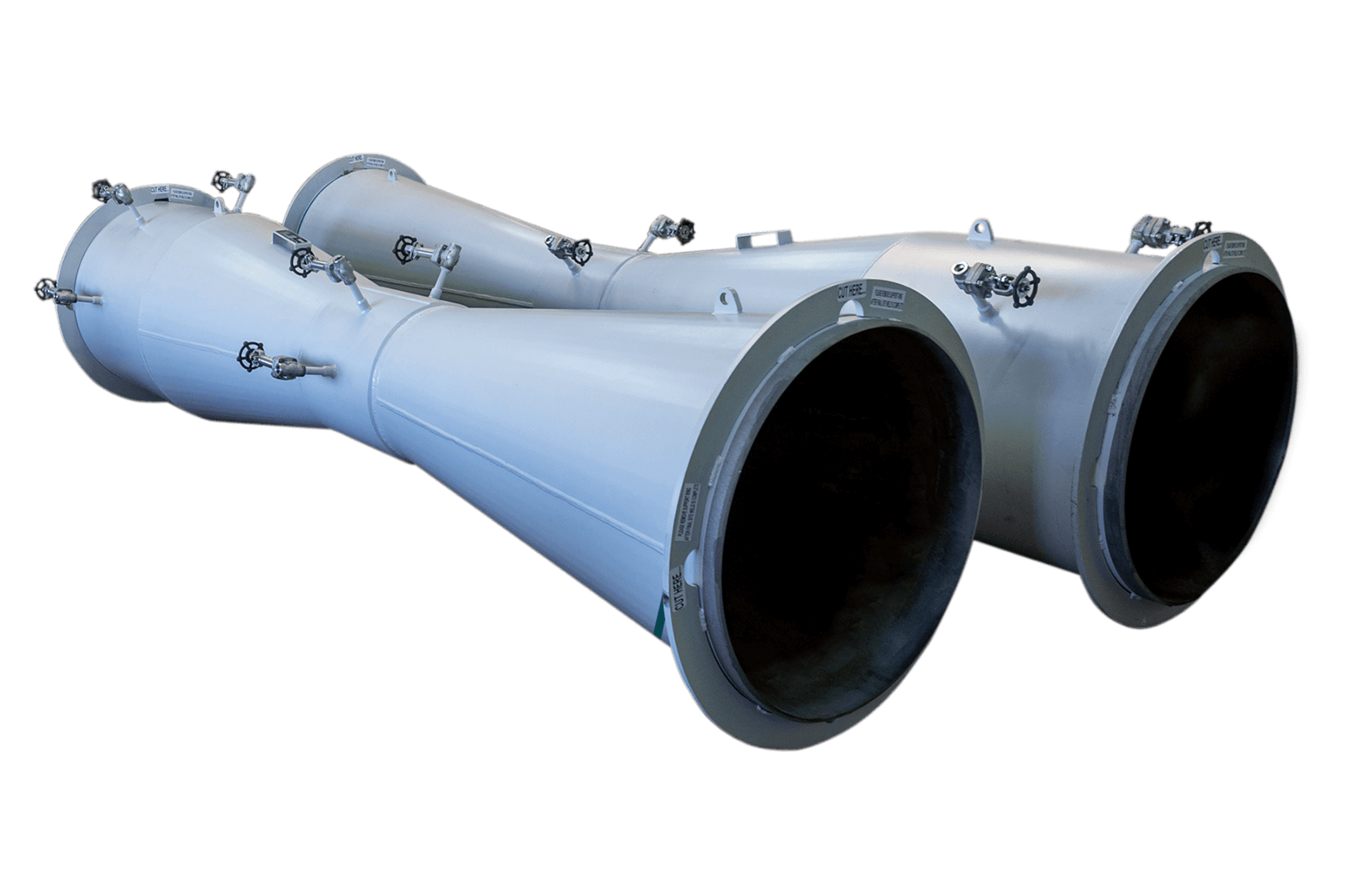

McMenon are specialists in the engineering and supply of venturi tubes in the demanding applications found in oil and gas, petrochemicals and process industries. We manufacture and supply the complete loop, from DP, pressure and temperature sensors and transmitters through to complete process automation systems.

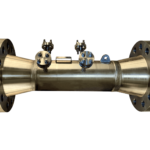

McMenon is also one of only a few DP flow suppliers to offer in-house calibration of large venturi tubes.

Without calibration, all venturi tubes have a larger uncertainty based on (for example) the ISO5167 published coefficient, which necessarily allows for manufacturing tolerances, etc.

At very high Reynolds Numbers, the uncertainty band is even wider. Calibration reduces the overall uncertainty by establishing the actual, as-manufactured discharge coefficient over the meter’s operating range of Reynolds Numbers.

![]()

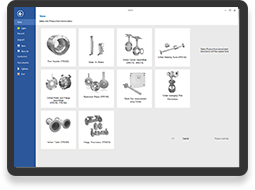

Sizing and selection is simplified by use of McMenon Solve, the ultimate tool for DP flowmeter sizing and more, used on-line

or off-line and available to download now

Special features

- Suitable for liquid, gas and steam flow measurement

- Accuracy ≤ ±0.5 % of actual flow rate

- Repeatability of measurement 0.1 %

- Lowest pressure loss in the family of

- DP primary flow elements

- Calibration may be performed if required

Applications

- Power generation

- Oil production and refining

- Water treatment and distribution

- Gas processing and transmission

- Chemical and petrochemical industry

- Liquified Natural Gas

Pipeline size range

- 2” – 72” and larger if required