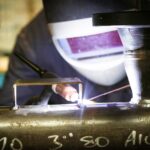

Fabrication and pipework services bespoke to customer needs…

With over 70 years of experience, McMenon Engineering Services can provide fabrication and pipework services bespoke to our customers’ needs.

All products are engineered and manufactured to the highest industry standards.

We can offer fabrication and pipework in a range of materials, thicknesses and diameters including, but not limited to, carbon steel, austenitic steel, nickel alloy steels, cobalt alloys and specialist corrosion and wear resistant coatings.

On request, our experienced engineers can offer site services for fabrication, pipework, welding and inspection capability.

We also offer specialist capabilities and procedures for welding and an extensive range of materials in accordance with ASME/ISO/BSEN supported by site approval for ISO 3834.

ISO 3834 is an international standard that ensures quality is built-in to welding processes. It gives a global recognition of our company’s capabilities and commitment to excellence.

Welding techniques

- Automatic Welding

- Semi-Automatic Welding

- Submerged Arc Welding (SAW)

- Flux-core Welding (FCAW)

- Manual Welding (SMAW)

- MIG Welding (GMAW)

- TIG Welding (GTAW)

- Vacuum Brazing

- CRA Weld Cladding

Welding Integrity & Assurance

- Procedure Qualification Records (PQR’s) and welder performance certificates supported by third party inspection authorities.

- Non-destructive and mechanical tests such as Macroscopic, Tensile, Impacts, Bends, DPI (Dye-Penetrant Inspection), MPI (Magnetic Particle Inspection), UT (Ultrasonic Testing), HT (Hydrostatic testing), Radiography (X-ray, Gamma), Weld Hardness checks, Adhesion tests, Paint thickness checks, and CSWIP (Visual inspection).

- Complete Welding and Material traceability.