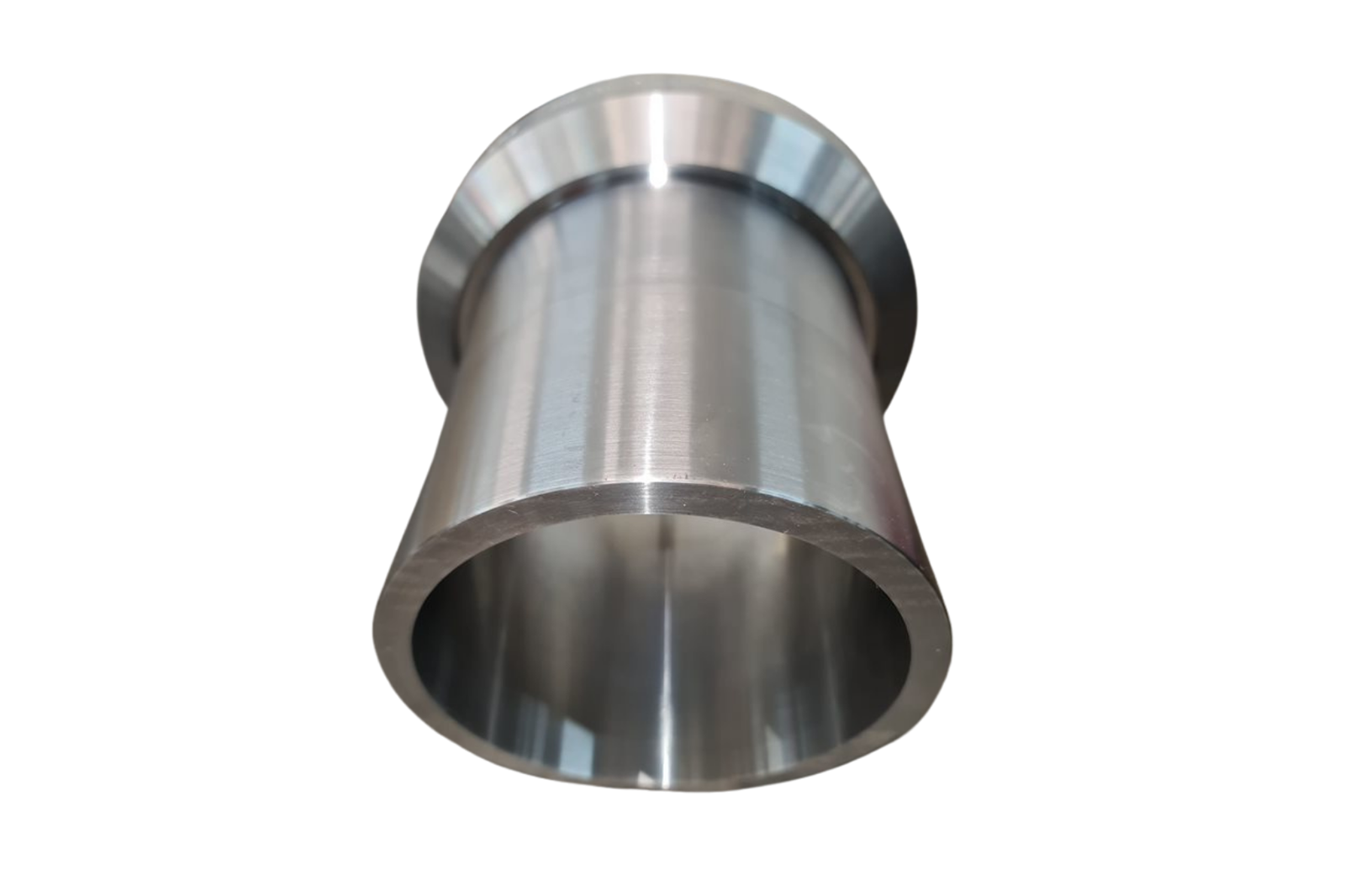

A flow nozzle offers excellent long term accuracy…

The flow nozzle is used for high velocity flow measurement where erosion or cavitation would wear or damage an orifice plate.

It does not rely on a sharp edge (which can degrade over time) for accuracy, therefore offering excellent long-term accuracy and it is often used for flow testing on steam-raising plant.

The discharge coefficient of a flow nozzle is such that a nozzle can measure approximately 55% higher flow rates than an orifice plate with a similar beta ratio and design differential pressure.

In the case of steam measurement, the pressure loss may not be significant as the effect is to beneficially heat the steam slightly.

![]()

Sizing and selection is simplified by use of McMenon Solve, the ultimate tool for DP flowmeter sizing and more, used on-line

or off-line and available to download now

Special features

- Maximum working pressure and temperature is limited by the application and material selection.

- Tappings ½ in. NPT as standard. Also available as ½ in. BSPT, ½ in. socket weld connection, ½ in. NB Nipolet, ½ in. NB Nipoflanges, etc.

- McMenon produces flow nozzles to the following design standards: ISA (1932); Long Radius (High and Low Rates) ASME throat tap nozzles; PTC6 The flow nozzle is available in designs for clamping between flanges (within the bolt circle )or as a weld-in unit.

Applications

- Steam

- Power

- Dry Gas Measurements

- Reference Flow Meters

- High Velocity applications

Pipeline size range (standard)

- 25 to 600 mm (1 in. to 24 in.)

- Fittings for larger pipelines are available to special order